Optimize Operations with Industrial IoT

to Drive Efficiency and Innovation

The shift to industrial automation and industrial IoT (IIoT) has sparked innovation in manufacturing, logistics, and robotics. Introducing artificial intelligence (AI), interoperability, and secure connectivity enables real-time monitoring, control, and optimization of processes, resources, and systems—all of which can lead to increased productivity, improved safety, and reduced costs.

The scalable, transformative Arm compute platform and strong ecosystem of partners allow our customers to operate seamlessly across a single architecture, from sensor to cloud, while addressing varied performance, real-time, functional safety, and security needs.

Key Use Cases for Industrial IoT

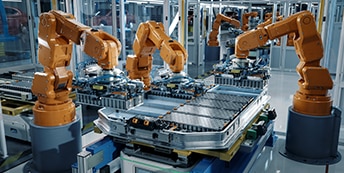

Predictive Maintenance

Industrial environments are evolving to achieve optimal performance and early issue detection. Advanced sensors and data analytics enable real-time monitoring and control of equipment, ensuring peak efficiency and reliability without relying on external cloud connectivity.

Automation of Manufacturing Processes

IIoT is transforming manufacturing processes by boosting efficiency and precision. Utilizing advanced automation technologies can reduce human error, enhance process accuracy, and increase efficiency.

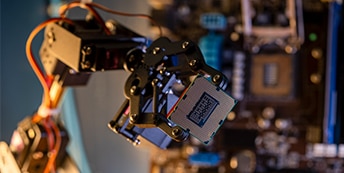

Advanced Robotics

Equipped with multiple advanced sensors, intelligent machinery can dynamically interpret its surroundings, enabling rapid task reconfiguration and superior decision-making across a vast range of requirements. This cutting-edge technology allows robots to navigate unpredictable terrains, and seamlessly adapt to changing environments and tasks.

Agricultural Systems

Agricultural systems are embracing cutting-edge innovation with Arm Cortex processors powering IoT devices. These intelligent systems analyze soil conditions, weather data, and crop health in real-time, enabling farmers to optimize resource usage and maximize crop yield. This advanced technology ensures efficient and sustainable farming practices.

The Foundation for IoT Innovation

Armv9 Architecture

The Armv9 architecture equips developers with the essential tools and environment to drive innovation in the rapidly growing IoT market. It offers unprecedented compute speeds for high-performance IoT applications and integrates with a comprehensive suite of security features to protect connected devices.

Arm Cortex-A CPUs

The high-performance Cortex-A series supports the complex compute needs of industrial autonomous systems and safety-critical applications like robotics, gateways, and PLCs.

Arm Corstone Subsystems

The Arm Corstone platform for IoT development simplifies design, enables differentiation, and speeds time to market. It balances performance and energy efficiency for edge AI workloads.

Arm Mali GPUs and ISPs

Mali's scalable, high-performance GPUs and ISPs address the complex safety requirements of industrial applications, such as fixed and mobile robots, smart manufacturing systems and production line monitoring.

Arm Ethos NPUs

As edge AI use cases grow more sophisticated, NPUs are crucial for running AI workloads alongside CPUs or GPUs. Arm Ethos NPUs pair easily with CPUs for AI acceleration at the edge.

Arm Kleidi Software

Developers need fast AI deployment and optimal performance for specific workloads. Arm Kleidi accelerates AI on Arm CPUs with seamless integration into popular ML frameworks.

Latest News and Resources

- NEWS and BLOGS

- White Papers

- Developer

Industrial IoT

Software-First Approach for

Industrial Automation and IoT Efficiency

Schneider Electric, Arm, and system integrators Witekio and Capgemini have produced a software-defined platform for industrial automation and energy management. This white paper provides details on the platform and how it reduced latency, enhanced cyber security, eased deployment and maintenance, and accelerated time-to-market.

Embedded Development

Embedded Development for Cortex-A and Cortex-M

Access key Arm developer resources to help you create innovative and high performing embedded systems.

AI and ML Solutions

Build, Train, Test and Deploy ML at the Edge

Access valuable resources to help streamline your development workflow and deploy ML at the edge.

Stay Connected

Stay up-to-date on the latest news, case studies, and insights by subscribing for updates.